|

|

Photo Courtesy of Roy Nagl Ancient Aviators Website |

|

Harry Atwood Designs Plane of Veneer (Reprinted from The Detroit News of Sunday, July 14, 1935.) The other day he emerged from jis voluntary seclusion with an airplane built of molded veneer, light and strong of construction, an efficient performer in the air. A Birch tree, six inches in diameter, provided the material. About $60 worth of Atwood's specially processed veneer was sufficient to build the ship. Atwood's goal is a one-piece plane, built entirely of laminated wood. His first thought of such a craft shortly after the World War but became discouraged when early experiments failed. The difficulty lay in making the wood strips and layers stick together. He went into the furniture business, but was forded out of that when the financial crash came in 1929. He returned to the chemical company which had employed him before the war and continued his research for a thermoplastic which would guarantee adhesion of veneer. Over a solid wooden mandril, sheathed in cellophane, Atwood places his thermo-plaster in paper form. Strips of veneer, twenty-thousandths of an inch thick, are wound around the form. Then comes a coating of rubber insulation. The entire form is wheeled into a steam room and cooked for three-quarters of an hour. After the cooking, the rubber insulation and mandrel are removed, leaving the veneer baked hard in the desired shape. Atwood claims his cooked veneer is lighter than dural, now commonly used in airliner construction, and costs much less. He applies a fire-proofing coating which makes the craft virtually immune to flames. (Editor's Note.---Later reports from the Federal Bureau of Air Commerce indicate a possibility that EB Atwood may be asked to build one of his planes for the Government under a contract which would pay for development costs.) courtesy of Steve Remington - CollectAir |

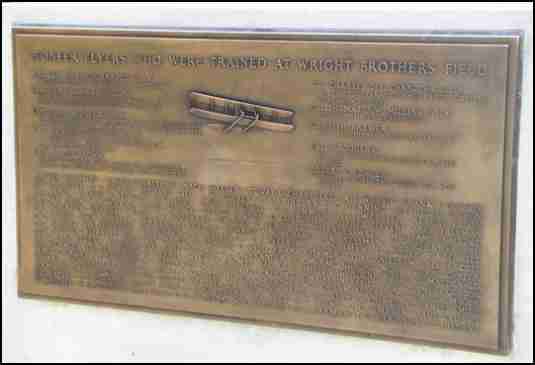

Wright-Patterson Air Force Base |

|

Photo courtesy of J. N. Parmalee The name of Harry N. Atwood is found on the plaque pictured above among the 119 names of pioneer flyers who trained at the Wright Brothers field at Huffman Prairie. To visit the page which lists all of the flyers, and which displays several photographs of the memorial, just click on: |

|